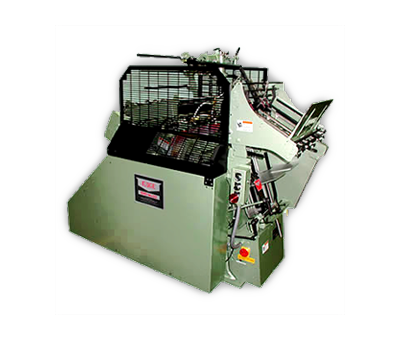

EHD

Often called “the workhorse of the industry”, the Kluge EHD is already a legend. Featuring speeds up to 3,300 impressions per hour, the EHD now comes with delayed delivery allowing it to accommodate sheets up to 17″x 24.75″ (431mm x 628mm), with up to 40 square inches of die area. Kluge’s patented Delayed Dwell technology allows the EHD to start on impression sooner, bottom out, and remain on impression longer doubling impression time with no loss of production speed and assuring flawless foil separation from the stock. A new, optional, freestanding mobile electronics console puts all press operations in one place for easy access. The same console can also serve as a workstation and toolbox.

Rugged, dependable and simple to operate, the EHD is known for providing years of reliable service in foil stamping, embossing and die cutting, and for over 25 years has been the standard by which all presses in its class are measured.

All Kluge presses can be supplied with the electrical specification of your country.

| Technical Specification EHD | |

| Max. Sheet Format: | 431 x 628 mm |

| Min. Sheet Format: | 101 x 127 mm |

| Max. Stamping Format: | 356 x 559 mm |

| Max. Speed: | 3300 strokes/h |

| Foil Feeds: | up to 3 |

| Hologram controllers | |

- Hologram Registration Unit – Provides the technology for registering holograms on the EHD

- Adjustable Impression – Decrease make-ready time. Impression can now be infinitely adjusted with the simple turn of a handle

- Mechanical Jogger – Prevents a saw-toothed edge on your finished pack

- Preload Magazine – Allows you to reload the press with new stock while the press is running

- Two-up Feeder – Allows the EHD to run Two-Up on certain jobs

- Electronic Foil Control System – Increased impression accuracy when foil stamping

- Reversible Register Cam – Saves time in make-ready when adjusting side registration

- Variable Speed Control – Control press speed with greater accuracy

- Dual Foil Rewind – Provides smooth rewind operations for different, multiple draw lengths or waste foil diameters

- Filler Plate – Replacement for die heating plate when die cutting

- Missed Sheet Detector – Prevents die, make-ready and press damage

- Foil Detector – Stops the press when a roll of foil is empty

- Lightweight Grid-etched Toggle Base – Gridded construction for greater accuracy in the die make-ready and weighs only 14lbs.

| Media | |

| Foil Stamping Hard Back Book Covers | Foil Stamping Pocket Folders |

| Heavy and Light Stock Feeding Demonstration | Die cutting Tags |