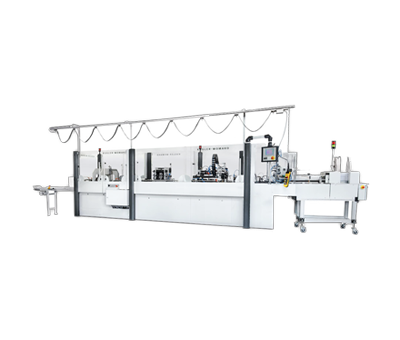

PassPort 2

Passport machine for laminating of covers and/or chip-inlays

The PassPort 2 machine laminates covers and/or chip-inlays onto layers sewn by PassPort 1.

All passport machines by Kugler-Womako adhere to the strict quality guidelines of the ICAO and ISO for “Machine Readable Passports (MRP) and electronic passports.”

The passport machine PassPort 2 can be combined with the following Kugler-Womako machines:

- PassPort 1 Collating, Sewing

- PassPort 3 Embossing, Folding, Die cutting

- PassPort 4 Numbering+Chip programming

Passport 2 basic equipment

- Feeder for sewn layers

- Seam gluing with cold glue

- Feeding of cover material, e-covers and/or chip-inlays

- Laminating of cover material or chip-inlays

- Pressing of layers

- Delivery

Features

- Suitable for (electronic) Machine Readable Travel Document (eMRTD) according to ISO and ICAO standards

- High productivity and reliable production in terms of quality and output

- Sophisticated technology for easy operation and maintenance

- Rigid design for increased life expectancy (>30 years)

- Modular layout in order to accomodate various types of passports and future upgrades

- Seam gluing with UV curable glue

- Secondary feeding and secondary lamination station for additional lamination of chip-inlays, to get chip-inlay and cover onto sewn layer in one working step

- Pile press

- Chip verification with automatic rejection of defective chip-inlays (without interruption of the production process), marking rejects by labeling

- Registration of Chip-UIDs used

- Inline connection to PassPort 1 and PassPort 3

- Optionally PUR hotmelt instead of cold glue