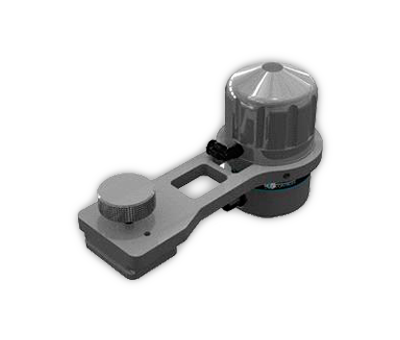

Reduce Fan-Out waste with adjustable nozzle

ABD II (the successor to ABD) is a unique fan-out correction system that functions fully contactless and with a very low constant air pressure using mechanically adjustable spray nozzles. This results in a constant print quality. The compressed air outlet of the completely revamped nozzle top is ring-shaped with an air gap of only 30 µm. As a result, air consumption has been reduced from 42 liters per minute to only 20 liters per minute. The compressed air exit reaches a speed of almost 1 Mach, resulting in substantially greater pressure on the paper web compared with the old design. If savings are also desirable in respect of time, labour and waste, then a “closed loop” can be created for the ABD II using mRC-3D cameras. The innovative flexible design facilitates the assembly of ABD II on any printing press.