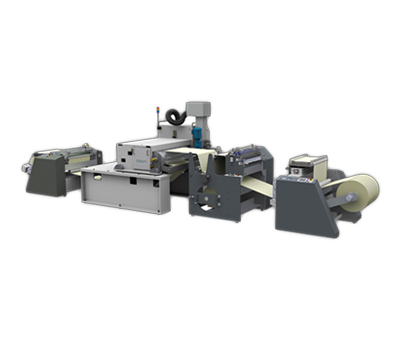

EB 30

Integrated Coating Module with ebeam Curing

EB30 is an integrated module that features an unwinder (LUW30) varnish/lamination station and a rewinder (LRW30) designed to run in-line with EBEAM systems for curing a substrate. It is also designed as a stand-alone unwinder, varnish station and rewinder system. It is a microcontroller controlled system that integrates its four component units in a client way and allows easy modification of the unit.

EB30 has a user-friendly touch screen interface that allows the operator to operate the machine in an easy way. The machine has an enhanced taper tension control algorithm that ensures that excellent rolls are made.

EB30 Coating Line highlights:

- Outstanding ink protection and excellent gloss matte and soft-touch finishes

- Increased heat resistance enables heat sealing to form pouches

- No harmful photoinitiators

- Cross-linking thin-film laminating adhesives

- Room temperature process, great for heat-sensitive substrates

- High process efficiency: instant curing, no post-process storage needed

| Technical Specification EB30 | |

| Web Width | 762 mm |

| Substrate Thicknesses | 50 – 200 µm |

| Semi-Rotary Web Speed | 55 m/min |

| Unwinder/Rewinder | |

| Unwind max. | 500 mm |

| Rewind max. | 500 mm |

| Core Diameter | 76,2 mm |

| Flexo Station | |

| Varnishing roller | 228 – 406 mm |

| Spot varnish option with registration and slow run | |

| Length approx. | 8,6 m |

| Media | |

| GM EB30 – EBEAM Coating line for food safe flexible materials. | GM EBEAM COATING LINE FOR FLEXIBLES |